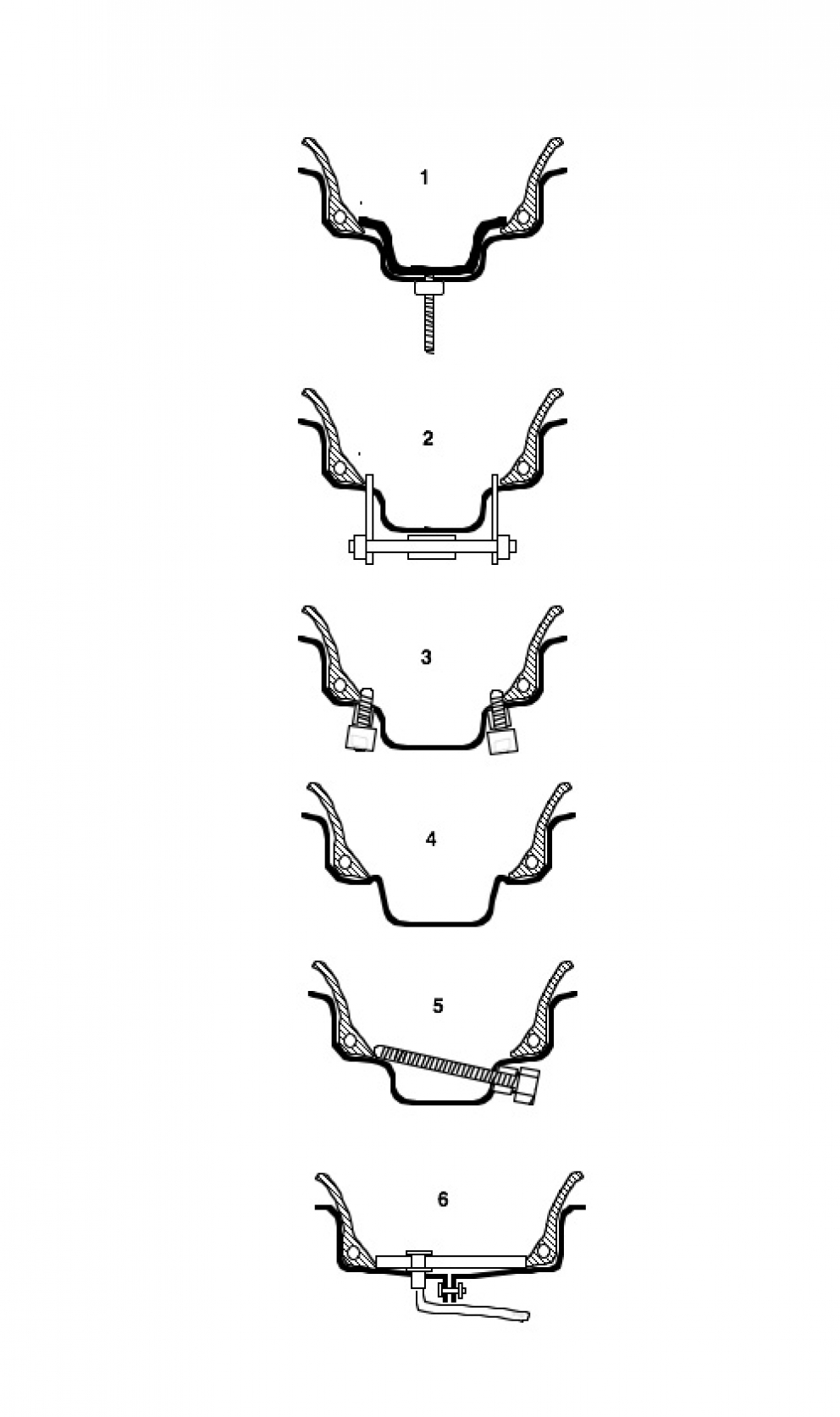

When I started coming to trials in the late ‘60s the 18” crossply TrialsMaster remould was in use, mainly on spoked Cannon type wheels, and system 1 was popular. the Y shaped steel piece was turned through 90 degrees to mount the tyre, then it was moved back to the position shown in the diagram. It was easy to puncture the tube when fitting the tyre, but it did work.

System 2 appeared when we went to the 15” radials we use today, and again it worked but was prone to cause punctures in the tube.

System 3 was Jack Pearce’s modification of an old system used with pointed bolts driven into the bead, however this can allow water penetration into the bead wire, leading to bead failure through corrosion. The Kincraft system with rounded bolts shown here worked well but needed maintenance. It was the first system that worked successfully tubeless, as pioneered by Sidney Hirst.

System 4, Safety Beads, is used on all of todays standard road cars, and it can work but mud eventually finds its way between the tyre sidewall and the side of the rim, eventually “jacking” the tyre over the safety beads. It is prone to fail all of a sudden on cross cambers unless you remove the tyre frequently to clean out the mud. It works quite well where higher tyre pressures (5+ psi) are used.

System 5 was intended for tubeless only operation, and worked well, as long as the long bolts were exactly the right length. It works best combined with safety beads as shown in version 4. A Dowty washer (steel with bonded on rubber seals as used in hydraulics) can be used to seal the bolt head to the threaded bush in the rim.

System 6 shows today’s split rim idea, pioneered by Ian Wright. It requires purpose made half rims, and a rigid plastic “band” which creates the air chamber. The rims have no sealing function at all. The tyre is held firmly against the side of the rim all the way round so no mud can get into the gap. They tyre never comes off, and no sealant is required. A later modification replaces the plastic band with a similar one made of aluminium after some plastic bands tended to “swell” in the centre and allow the tyre to deflate. The aluminium band solves all the problems.

No doubt you will be aware of other systems used over the years?

Julian.